The meaning of butterfly valve and the problems that are easily overlooked in the use process

In production and life, the emergence of valves is that the utilization rate of their valves and accessories is getting higher and higher, such as check valves, check valves, electric butterfly valves, pneumatic butterfly valves, rubber soft joints, electric ball valves, one-way valves, and wafer butterfly valves. , filter, etc., which have brought great convenience to production and life. Today, I will share with you the meaning of butterfly valves and some problems that are easily overlooked in their use.

In the 1930s, the United States discovered the butterfly valve, and it was introduced to Japan in the 1950s. It was not widely used in Japan until the 1960s, and it was implemented in my country after the 1970s. Compared with gate valve, butterfly valve has short opening and closing time, small operation moment, small installation space and light weight. And the butterfly valve is easy to combine with various driving devices, and has excellent durability and reliability.

The fault of the rubber soft sealing butterfly valve is that when it is used for economical use, cavitation will occur due to improper use, which will cause the rubber seat to fall off and damage. For this reason, metal-sealed butterfly valves have been developed internationally, and the cavitation area has been reduced. In recent years, my country has also developed metal-sealed butterfly valves. In Japan, comb-shaped butterfly valves with cavitation resistance, low oscillation and low noise have also been developed in recent years.

Generally, the life of the sealing seat is 15-20 years for rubber and 80-90 years for metal under normal conditions. But how to choose correctly should be in accordance with the requirements of the working conditions.

The relationship between the opening of the butterfly valve and the flow is basically a linear proportional change. If it is used to control the flow, its flow characteristics and the flow resistance of the piping are also closely related. For example, the two pipelines are installed with the same valve diameter and method, and the pipeline loss tracking coefficient is not the same, the flow of the valve will also be very different. New Year's Eve.

If the unsightly valve is in a state of large fluctuations, the back of the valve plate is prone to cavitation, which may damage the valve, and is generally used at a distance of 15°.

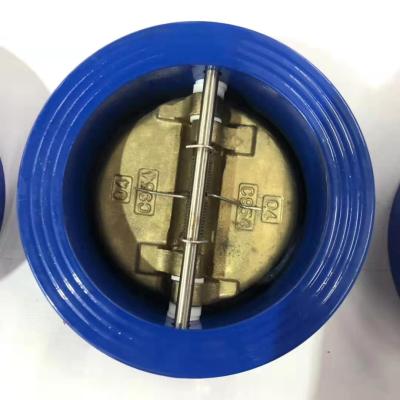

When the butterfly valve is in the middle opening, the opening shape formed by the valve body and the front end of the butterfly plate is centered on the valve shaft, and the two sides are in a state of complete disparity. Therefore, one side of the valve body and the valve plate form a nozzle-shaped opening, and the other side is similar to a saving hole-shaped opening. The nozzle side has a much faster flow rate than the saving side, and a negative pressure will be generated under the valve on the saving side, which tends to cause Shows the rubber seals come off.

The operating torque of the butterfly valve is different due to the opening degree and the intention of the valve opening and closing. The horizontal butterfly valve is especially a large-diameter valve. Due to the depth of water, the torque generated by the difference between the upper and lower heads of the valve shaft cannot be ignored. In addition, when an elbow is installed on the inlet side of the valve, a bias flow is formed, and the torque will increase. When the valve is at the center opening, the operating mechanism needs to be self-locking due to the water flow torque.