Background of Butterfly Valve

Butterfly valve is a type of valve that uses a spherical butterfly plate as the opening and last component and turns with the valve stem to open, close and alter the fluid channel. the butterfly plate of the butterfly valve is set up in the diameter route of the pipe. in the cylindrical channel of the butterfly valve frame, the disc formed butterfly plate rotates around the axis of the valve stem at an perspective among 0 ° and 0 °. whilst the butterfly plate is at 0 °, the valve is closed, and when the butterfly plate is at ninety °, the valve is absolutely opened. the existing butterfly valve is specifically composed of valve frame, valve stem and butterfly plate. the valve body is ready with a valve seat. the butterfly plate is constant with the valve stem. the valve stem is mounted in the valve frame radially and may rotate. the butterfly plate can be matched with the valve seat and sealed. consistent with the valve stem shape, it may be divided into unmarried axis and double axis (two half of axes) systems. when a butterfly valve is utilized in a huge diameter pipeline, particularly below excessive-strain situations, the medium in the pipeline exerts extraordinary pressure at the butterfly plate. when the butterfly plate is opened, the torque borne by way of the valve stem is huge, and the torque required for beginning the valve is also huge. beginning the butterfly plate is laborious, and the output torque of the actuator is likewise huge, resulting in a massive valve shape. inside the creation venture of massive-scale hydropower station, the water head is very excessive and the glide is big. the high-stress big caliber butterfly valve decided on wishes to meet both the dynamic water close-off valve and the non flat pressure transfer valve. for this excessive requirement, the prevailing general butterfly valve can not meet.

The content of the utility model is to overcome the disadvantage of the existing universal butterfly valve that it is hard to open the butterfly plate when it is used under the working conditions of large diameter and high pressure, the utility model provides a double shaft double plate butterfly valve, which has the characteristics of simple structure and labor saving when opening the butterfly plate, and is suitable for the working conditions of large diameter and high pressure. The technical scheme of the utility model is that the double axis double plate butterfly valve comprises a valve body, an upper valve rod, a lower valve rod and a large butterfly plate, the valve body is provided with a valve seat, the large butterfly plate is fixed with an upper valve rod and a lower valve rod, the upper valve rod and the lower valve rod are arranged in the same axis and can rotate relative to the valve body, the large butterfly plate is sealed after being buckled with the valve seat, the large butterfly plate is provided with a through hole and a small valve seat, and the small valve rod is arranged between the upper valve rod and the lower valve rod, The small valve rod is fixed with a small butterfly plate which is sealed and matched with the small valve seat. One end of the small valve rod penetrates the lower valve rod and the end of the small valve rod is placed outside the valve body. The other end of the small valve rod is supported by the upper valve rod. The small valve rod can rotate relative to the upper valve rod and the lower valve rod. The small valve rod is sealed with the lower valve rod. The lower end face of the upper valve rod is provided with a blind hole, and the small valve rod is inserted into the blind hole. The small butterfly plate is fixed with a small sealing ring through a small pressing plate. The small butterfly plate is provided with two ear plates, and the small valve rod passes through two ear plates and is fixed with the ear plate through a taper pin. A packing is arranged between the small valve rod and the lower valve rod. The lower valve rod is limited by the lower end cap fixed on the valve body, and the packing is compressed by the lower gland fixed on the lower end cap. The utility model has the following beneficial effects. Because of the above scheme, when the valve is opened, the small butterfly plate is first opened for pressure relief, and then the large butterfly plate is opened. Because the pressure of the medium acting on the small butterfly plate is small, the small butterfly plate is easy to open. After the small butterfly plate is opened, the medium passes through the valve body, the pressure difference on both sides of the large butterfly plate decreases, and the pressure of the medium acting on the large butterfly plate decreases, making it easier to open the large butterfly plate. The utility model is suitable for large caliber High pressure working conditions.

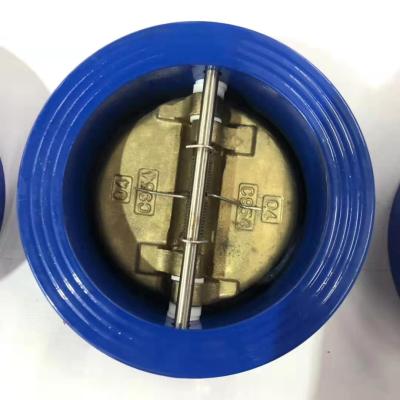

Figure 1 is a structural sectional view of the utility model. In the figure, 1 - valve body, 2 - upper valve stem, 3 - lower valve stem, 4 - large butterfly plate, 5 - valve seat, 6 - through-hole, 7 - small valve seat, 8 - small valve stem, 9 - small butterfly plate, 10 - small pressing plate, 11 - small sealing ring, 12 - ear plate, 13 - taper pin, 14 - packing, 15 - lower end cap, 16 - lower Gland ο.