Different installation requirements for rubber soft joints

Rubber soft joints have been widely used in the industry. The installation of rubber soft joints requires different installation requirements according to different types of rubber joints. Threaded screwed rubber joints: Pay attention to the installation of screwed rubber joints. The pipe fittings are laid flat on a horizontal surface. When installing, it is necessary to screw the threaded structure into the lifting section of the pipe fittings, and then screw the other section of the pipe fittings, keeping it on the horizontal plane to prevent uneven force during the installation process. As a result, the rubber joint is torn. Next, tighten the screw thread with a hand or a wrench, and then fix the two ends of the screw rubber joint box on an object that is not easy to stretch or distort!

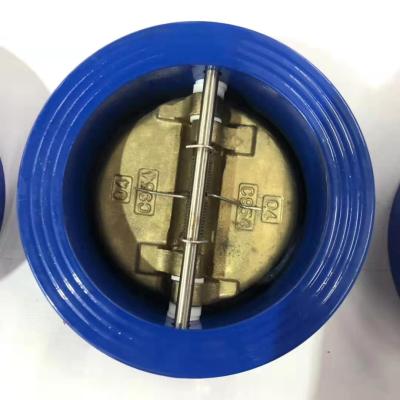

The device for connecting the clamp to the rubber joint:

Clamp-type rubber joints use clamps instead of flanges and bolts. When installing, the two nozzles of the clamp-type rubber joints can be separately sleeved on the pipes to be connected, and the rubber joints can be fixedly connected to the pipes through the clamps. . When the clamp is connected to the rubber joint, the clamp can be loosened, so as to achieve the purpose of compensating for the displacement of the pipeline due to thermal expansion and contraction and water conveyance.

The device of flange type rubber soft joint:

1. Flexible rubber joint When the pipeline is constructed, it must be in a natural state, and the product should not be artificially deformed when it is installed.

2. When installing a rubber joint, the screw rod of the bolt should extend to the outside of the joint, and the bolts on the end face of each flange should be repeatedly and evenly tightened by means of diagonal pressure to prevent pressure deviation.

3. When the displacement of the pipeline is greater than the additional compensation amount of the joint, the number of joints should be added to parallel the displacement. It is forbidden to adjust the excess tolerance of the pipeline, so that the joint is in additional deflection displacement and error conditions, and cannot exceed the limit. (Extension, displacement, deflection, etc.), see the table below for the specific device data used.

4. For high-rise water supply or suspended water supply, the pipeline should be fixed on the hanger, bracket or anchor frame, and the joint should not be allowed to accept the pipeline's own component and axial force, otherwise the joint should be equipped with an anti-pull device (the receiving force must be greater than that of the pipeline). axial force).