Limit Switch Box

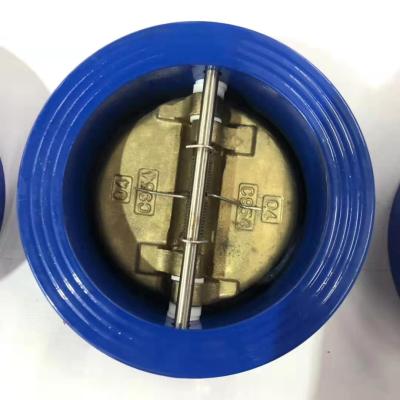

Resilient seated butterfly valve is a double flanged design which can be used for dead-end service .This butterfly valve series has many of the design features and benefits such as high Cv ratings ,minimum parts exposed to the line media ,greater reliability and a proven record of long service life .A major design advantage of this valve product lines is international compatibility.

Product Details

Technical Parameters:

| Size | DN32-DN600 | DN650-DN2000 |

| Working pressure | 16Bar | 10Bar |

| Shell | 24Bar | 15Bar |

| Seal(Air) | 6Bar | 6Bar |

| Operating Temperature | -40℃~+160℃ | |

| Operating Environment | Ballast and bilge system Chemical processing | |

| Desalination plants Drilling rigs Drinking water | ||

| Dry powder Food and beverage Gas plants | ||

| HAVC Mining industry Paper industry Sand handling Seawater Sugar industry | ||

| Thermo technical water treatment Waste water | ||

| Driving method | Hand Lever Worm Gear Electric Pneumatic | |

Executive Standard:

| Design Standard | EN 593 , MSS SP67 API 609 BS5155 |

| Inspection & Test | API 598 ISO 5208 EN 12266 |

| End Standard | ANSI B16.1 CL. 125LB & B16.5 CL. 150LB |

| AS 2129 Table D & E BS 10 Table D & E | |

| DIN 2501 PN6, PN10 & PN16 | |

| EN 1092 PN6, PN10 & PN16 | |

| ISO 2531 PN6, PN10 & PN16 | |

| ISO 7005 PN6, PN10 & PN16 | |

| KS B 1511 / JIS B 2210 5K & 10K | |

| MSS SP44 CL. 150LB AWWAC207 | |

| SABS 1123 Table 1000/3 & Table 1600/3 | |

| Face to Face | ISO 5752 , EN 558 , MSS SP67 and API 609 DIN3202 |

| Top Flange | ISO 5211 |

Main Material:

| Name | Material |

| Body | Cast Iron Ductile Iron Carbon Steel Stainless Steel AL-Bronze |

| Disc | Ductile Iron Carbon Steel Stainless Steel AL-Bronze |

| Shaft | Stainless Steel Monel K500 |

| Seat | BUNA NBR EPDM VITON PTFE HEPDM Neoprene Hypalon Natural rubber |

Product form

Related News

China Refrigation Equipment Exhibition

2023-04-13

What Is The Advantage for Butterfly Valve

2023-04-12

Pressure Test Method Of Check Valve

2022-12-22

Submitted successfully

We will contact you as soon as possible

Close