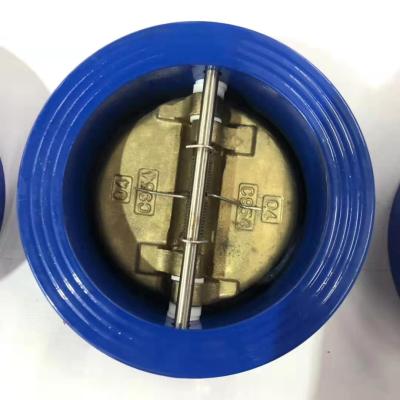

PTFE Coated Butterfly Valve split type

Tetrafluoride butterfly valve is to adapt to some corrosive environment with strong acid and alkali, petroleum, chemical, food and other special fields, in the conventional butterfly valve valve and valve plate lined with ptfe, so that the medium and valve body isolation, to achieve anticorrosive effect.

Tetrafluoride butterfly valve is to adapt to some corrosive environment with strong acid and alkali, petroleum, chemical, food and other special fields, in the conventional butterfly valve valve and valve plate lined with ptfe, so that the medium and valve body isolation, to achieve anticorrosive effect.

Technical Parameters:

Size | DN50-DN600 |

Working pressure | 10Bar |

Shell | 15Bar |

Seal(Air) | 11Bar |

Operating Temperature | -20℃~+180℃ |

Operating Environment | Ballast and bilge system Chemical processing Desalination plants Drilling rigs Drinking water Dry powder Food and beverage Gas plants HAVC Mining industry Paper industry Sand handling Seawater Sugar industry Thermo technical water treatment Waste water |

Driving method |

Executive Standard:

Design Standard | EN 593 , MSS SP67 API 609 BS5155 |

Inspection & Test | API 598 ISO 5208 EN 12266 |

End Standard | ANSI B16.1 CL. 125LB & B16.5 CL. 150LB AS 2129 Table D & EBS 10 Table D & E DIN 2501 PN6, PN10 & PN16 EN 1092 PN6, PN10 & PN16 ISO 2531 PN6, PN10 & PN16 ISO 7005 PN6, PN10 & PN16 KS B 1511 / JIS B 2210 5K & 10K MSS SP44 CL. 150LB AWWA C207 SABS 1123 Table 1000/3 & Table 1600/3 |

Face to Face | ISO 5752 , EN 558 , MSS SP67 and API 609 DIN3202 |

Top Flange | ISO 5211 |

Main Material:

Name | Material |

Body | Cast Iron Ductile Iron Carbon Steel Stainless Steel AL-Bronze |

Disc | Ductile Iron Carbon Steel Stainless Steel AL-Bronze |

Shaft | Stainless Steel Monel K500 |

Seat | PTFE |

Related News

Submitted successfully

We will contact you as soon as possible