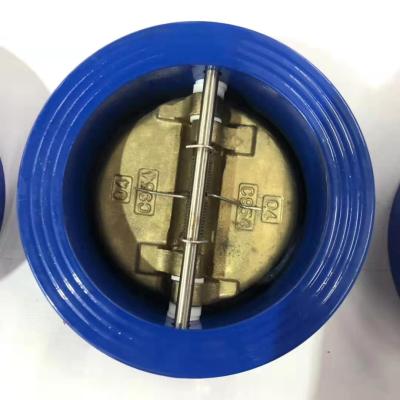

WECO Butterfly Valve without pin

100% bi-directional tight shut-off. Installation without restrction in direction of flow.Reduced weight and overall dimensions.Low pressure loss and reduced energy costs. High Kv/Cv values.

Easy to clean and disinfect for potable water systerms etc.

Self cleaning (no residue will be trapped)

Good resistance to corrosion.

100% bi-directional tight close-off. set up without restrction in path of waft.decreased weight and overall dimensions.low pressure loss and decreased power prices. immoderate kv/cv values.

Clean to clean and disinfect for potable water systerms and lots of others.

Self cleansing (no residue may be trapped)

Accurate resistance to corrosion.

Technical Parameters:

| Size | DN50-DN300 | |

| Working pressure | 16Bar | 10Bar |

| Shell | 24Bar | 15Bar |

| Seal(Air) | 6Bar | 6Bar |

| Operating Temperature | -45℃~+150℃ | |

| Operating Environment | Ballast and bilge system Chemical processing | |

| Desalination plants Drilling rigs Drinking water | ||

| Dry powder Food and beverage Gas plants | ||

| HAVC Mining industry Paper industry Sand handling Seawater Sugar industry | ||

| Thermo technical water treatment Waste water | ||

| Driving method | Hand Lever Worm Gear Electric Pneumatic | |

Executive Standard:

| Design Standard | EN 593 , MSS SP67 API 609 BS5155 |

| Inspection & Test | API 598 ISO 5208 EN 12266 |

| End Standard | ANSI B16.1 CL. 125LB & B16.5 CL. 150LB |

| AS 2129 Table D & E BS 10 Table D & E | |

| DIN 2501 PN6, PN10 & PN16 | |

| EN 1092 PN6, PN10 & PN16 | |

| ISO 2531 PN6, PN10 & PN16 | |

| ISO 7005 PN6, PN10 & PN16 | |

| KS B 1511 / JIS B 2210 5K & 10K | |

| MSS SP44 CL. 150LB AWWA C207 | |

| SABS 1123 Table 1000/3 & Table 1600/3 |

Related News

Submitted successfully

We will contact you as soon as possible